I’ve been looking for a simple project to play with since moving states. My goals for a simple project would be:

- Extend my current knowledge and experience;

- Useful in terms of my other projects;

- Something that I haven’t tried before;

- Uses components that I have on-hand

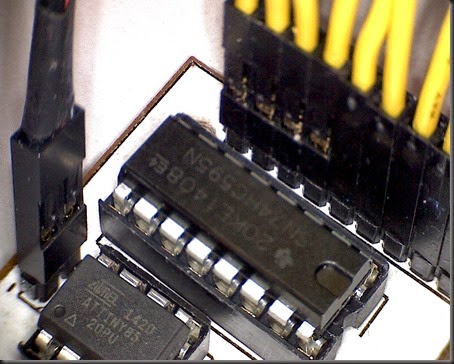

While hunting around for projects to play with, I found the “DIY-Duino” on Instructables by robonerd (http://www.instructables.com/id/DIY-Arduino-or-The-DIY-Duino/). The DIY Duino is a simplified Arduino clone that works on a single sided PCB and has a minimum of elements ( a couple of resistors, a couple of ceramic and electrolytic capacitors, a 16MHz crystal, a bunch of female pin headers an LED and a pushbutton switch).

This project was a leap of faith for me because I was using someone else's design where the circuit template was a bitmap image (all of that nasty antialiasing means that the edges aren’t terribly crisp, compared with a raster image).

The first step was to transfer and etch the board. This was done with a reasonable amount of success. My only problems were with the antialiased image tending to make bridges between some of the close solder pads. That’s OK … I was expecting that.

I also had some gaps in some of my traces, that was down to the toner transfer and entirely my fault. I ended up bridging the only significant gap with a piece of cut-off wire (a leg from a previously used resistor … I keep most of my cut-offs for this purpose).

My longer term goal for this board will be to drive an automatic watering system for my veggie patch (I may need to make a few more) and will connect in an SPI (or I2C) network.

After the etch/inspection and correction process, it was simply a matter of populating the board.

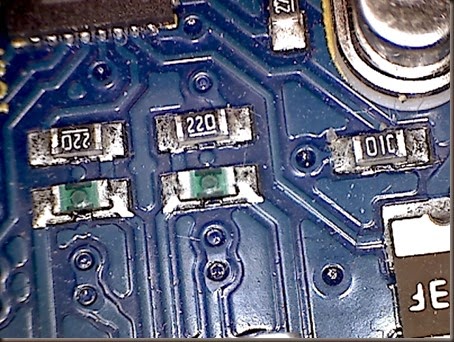

Robonerd used jumper wires as bridges on the board (there are three of them) whereas I used 0Ω Resistors. The main reason for this is that I’m not all that keen on the appearance of cut-off jumper wire on the component side of the circuit … plus, the resistors are better insulated. Apart from that, it is an entirely personal choice (AFAIC).

When the board was all populated and soldered up, I got down and did some testing.

The voltage between the input power and the LM780 was 7.89V (battery not at full charge). The voltage between the LM780 and the 2nd capacitor was 4.98V, well within the 5% tolerance for the LM780 and safe for the ATMEGA329P chip.

Next, I did a continuity test throughout the board and found that all of the traces were good and the pin headers were correctly connecting to the DIP28.

Also, I made sure that the LED indicator did was it was supposed to do.

I will still need to test the circuit with the ATMEGA328P in place, but I kinda have to wait until my AVRSIP arrives (I just bought one from adafruit).

Well … that’s it for now. I’ll report later on how the circuit performs as a Duino clone.